Team and Charter

In 2022 my senior design capstone team set out to create a Vehicular Lab Automation Device to showcase our ability as engineers. The device is intended for use in a lab environment to automate basic physical processes thereby increasing efficiency and decreasing workload.

Our team consisted of the following:

- Sponsor: Dr Keith Brown

- Advisor: Prof. Anthony Linn

- Team VLAD Members

- Adam Bahlous-Boldi

- Miguel Ianus-Valdivia

- Kyle Fieleke

- Vlad Pyltsov

- Abin Binoy George

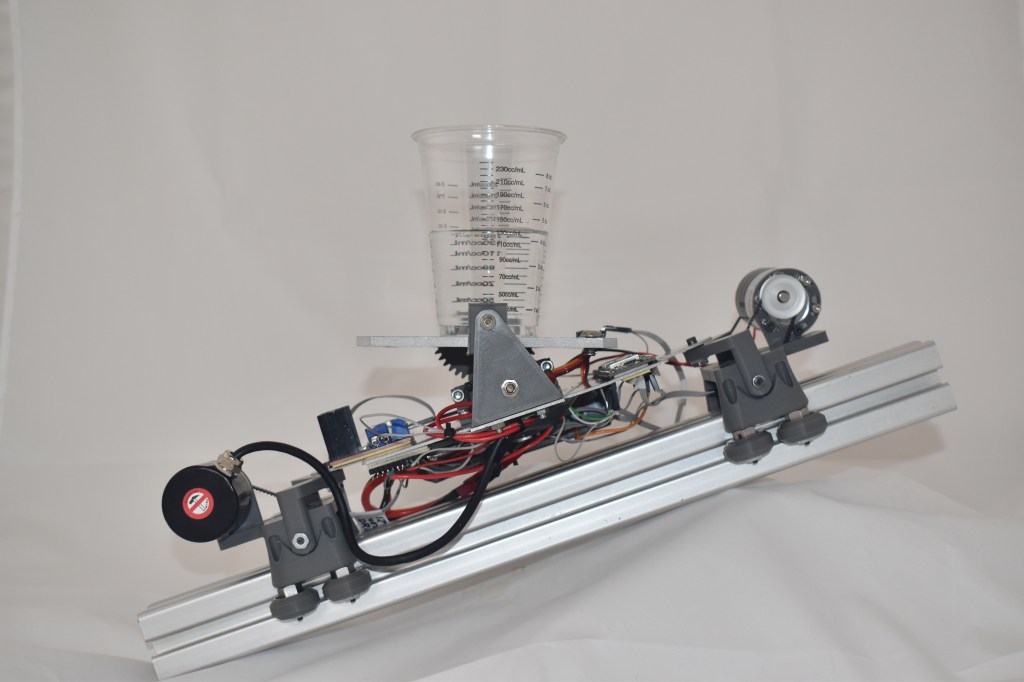

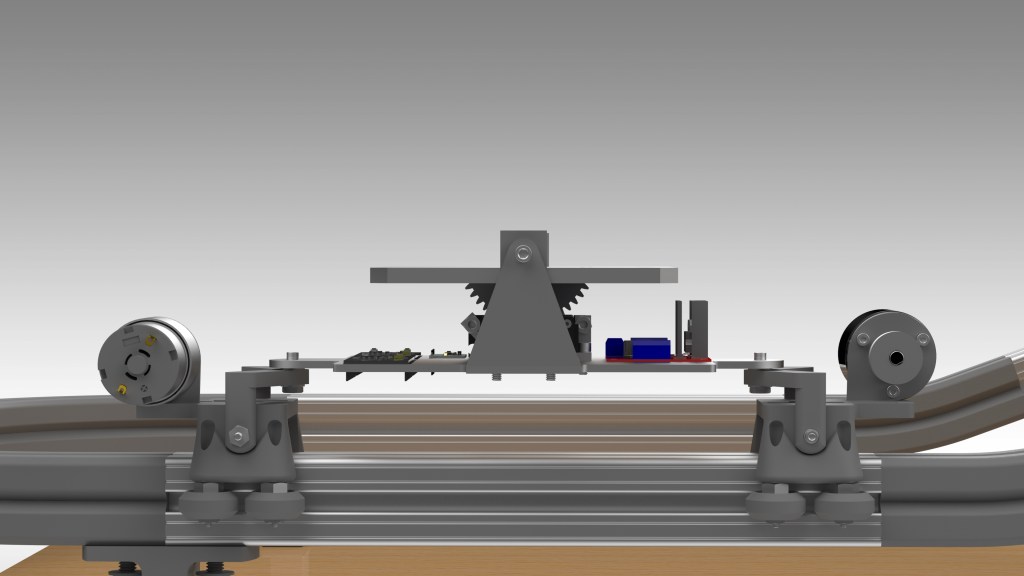

Our objective was to create a modular device that could move instruments in three dimensions around a lab environment without supervision. It needed to be able to accommodate many end-effectors for a variety of laboratory uses. With deliberation and consultation from our faculty partners, we settled on an 80-20 rail design because it would be comparatively easy to replicate in most lab environments and we would be able to design and build it with the time and tools available. See real life pictures at the end!

Design Elements

The VLAD consists of four primary systems:

- Track and mounting system

- Wheelbase and chassis system

- Tilting platform

- Electronics and PID controls

The track and mounting system uses normal laboratory clamps and 3D-printable mounts which allow it to connect to vertical and horizontal surfaces as seen in the photo above. 3D-printed track pieces allow it to turn left, right, up, and down while still primarily using standard 80-20 rail.

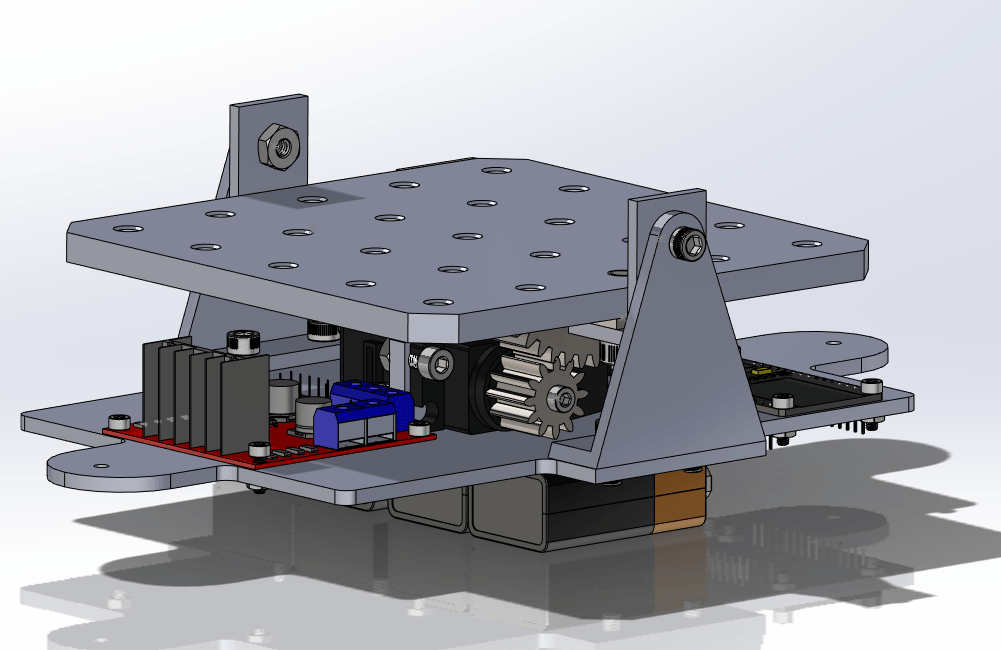

Both wheelbases rendered above have two degrees of freedom and consist of 5 wheels, a plastic wheelbase, one DC motor, and a connecting rod to attach it to the chassis which houses the electronics. The wheel on the top of the 80-20 is driven directly by the DC motor using a ribbed band (not pictured) where the side wheels rotate freely and keep the device upright.

The tilting platform seen above is monitored by the IMU attached to the bottom and tilted back to level using gears. The IMU measures the angle/movement and sends data to the microcontroller which signals a servomotor to tilt the platform. The holes on the platform are for screwing one’s end-effector of choice onto it.

Finally, the electronics and PID system monitors and controls the VLAD to keep everything running smoothly.

Final Products

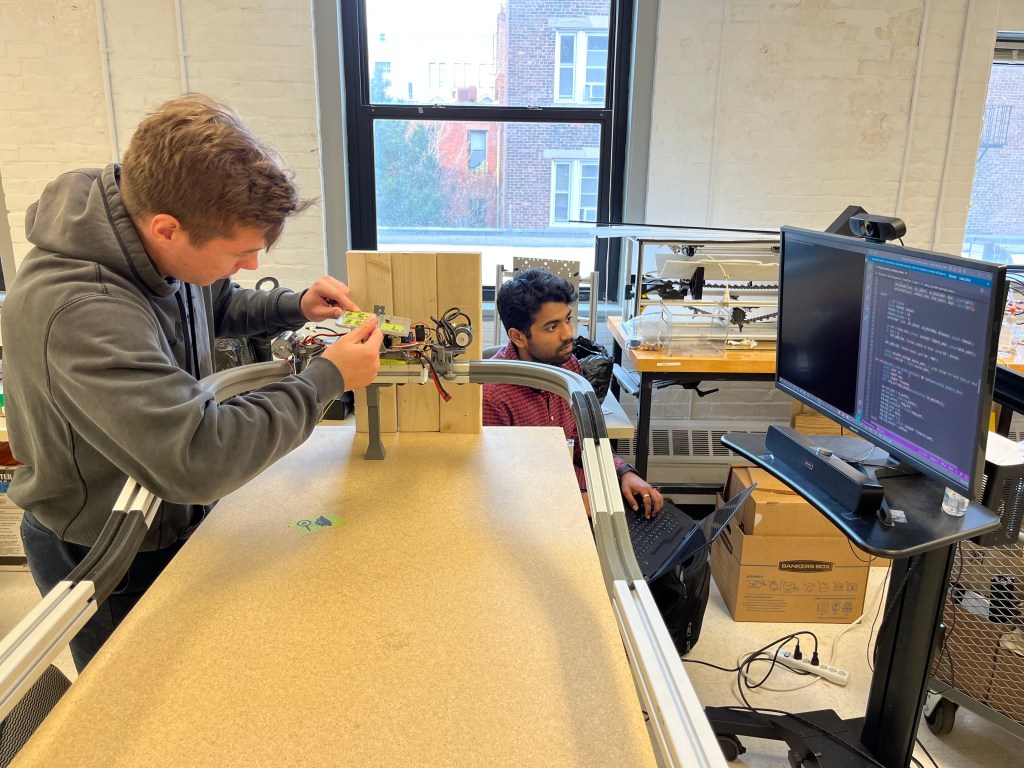

There were many iterations throughout our design process that ended in success. See the VLAD in action above and our final report below.

Next steps for this project would be to design a series of end-effectors used for moving beakers, pushing buttons, and whatever other physical processes a lab might need to automate.

Documentation

Please see the attached link for CAD files and code.

Thank you to Dr. Brown and Professor Linn for making this project possible. And thank you to my team for making it a reality!